One reason I attended the Miami bat show was to find out why it is so hard to get torque information when tightening prop nuts. From my recent blog that addressed which nuts goes on in what order, what was missing was a reasonable description as to how tight these nuts should be against the hub of the propeller. Scanning the Internet does not provide accurate information regarding torque values for the various diameter shafts, which seems odd to me. I was determined to find out why that is the case.

Thankfully I met an engineer at Michigan Wheel who was more than happy to discuss this subject. Kevin Mitchell is a naval architect, and VP of Sales and Marketing for Michigan Wheel, the well respected prop manufacturer based in Grand Rapids, Michigan. He quickly admitted my question is the Holy Grail within his area of interest, and that he had only seen a chart once in his career that dated back to the 1950s. But he could not find it again.

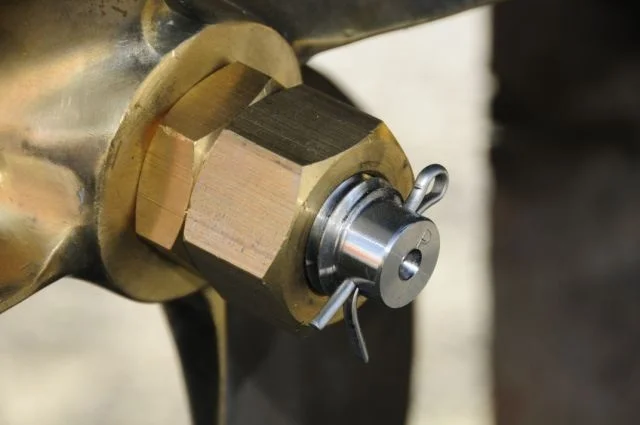

As Mitchell explained, the prop nut(s) create an "interference fit" of the hub to the taper of the shaft, and that there are many factors that play into this. The forces incolved include the shaft torque from the engine/gears, prop material, contact area, and hub and shaft diameters. This is unlike outboard engines, where the manufacturer controls all of these elements, so torque specifications can universally be provided as a set standard. Inboard boat builders do not consistently know the interaction of these values, so it is difficult to create a meaningful chart for properly torquing prop nuts across the many variations of diameter, material, and surface areas.

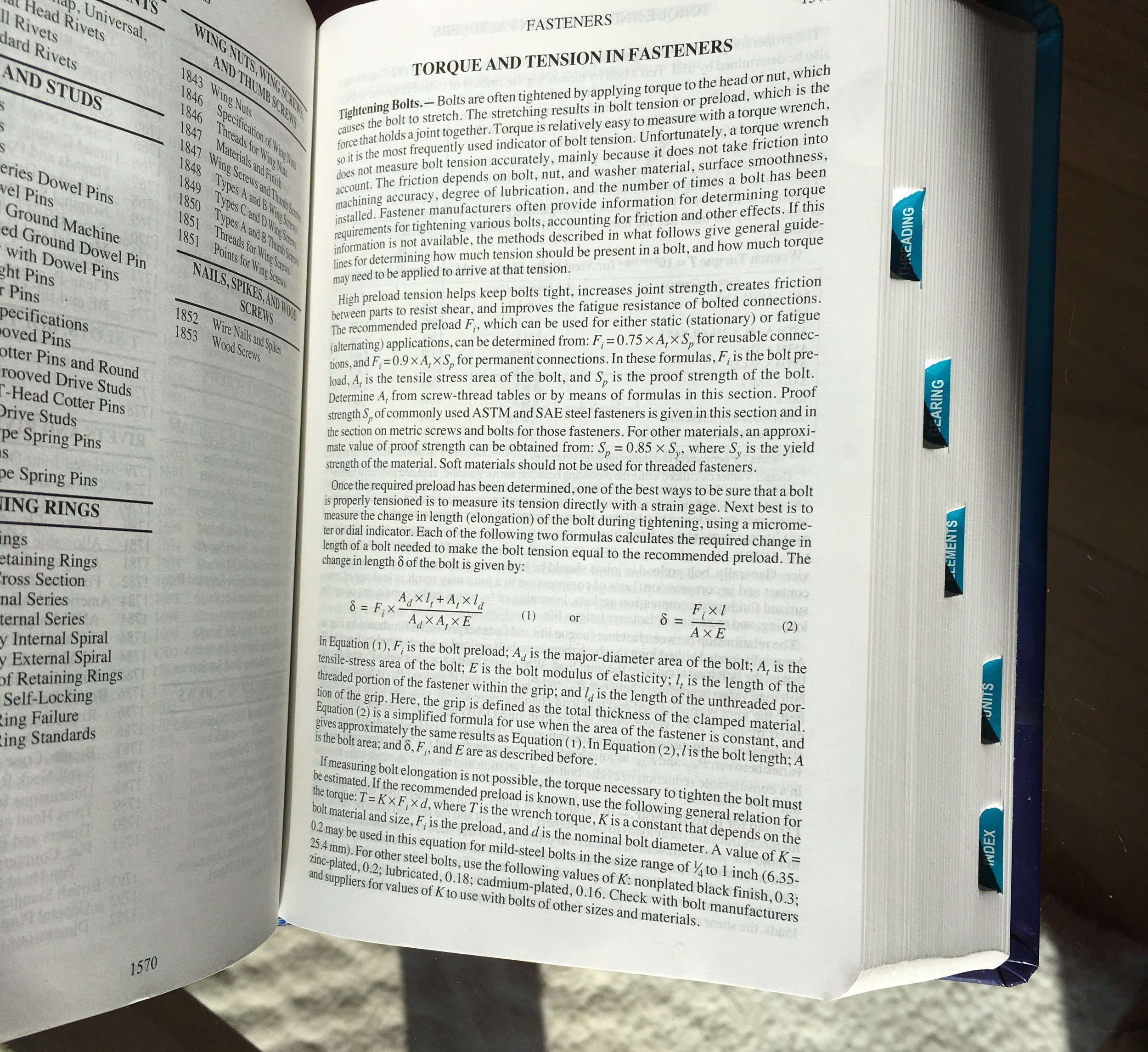

He did reference several resources for further investigation. The Machinery's Handbook is a deliciously complex marvel of engineering information, and there is an entire chapter on torque and tension fasteners. One can be quickly lost in the complexity of this subject, but you soon realize it is not a simple subject to conclude general guidelines from. The wrench torque formula is simple enough, but not really: Wrench Torque T = 10 to the (b+m log d). But torque wrenches do not take into account friction, so are only accurate to +/- 25 percent.

Another resource he mentioned is SAE's J755 Shaft Taper Standard. I contacted customer support at SAE and am awaiting a response.

The final issue he explained was the inherent difficulty of securing the propeller shaft when tightening propeller nuts. With the boat on the hard, invariably the yard guys place a block of wood through the propeller to keep it from turning. Concentrating all that force on a small edge of a blade can easily create a slight deflection on that edge. He said it happens all the time.

As a side note, Mitchell said the initial thrust of power from the engine sets the prop on the shaft, making the key used to install the prop somewhat unnecessary beyond that initial application of power.

AND FINALLY...

As a final note of this subject, I asked Dave Gerr about it. Naval architect and author of many books, his response pretty much sums up the subject:

Except for outboard and sterndrive propellers, which have manufacturer-speced torque, there isn’t a standard torque spec for propeller nuts. Here’re the directions I give in The Nature of Boats, page 260:

"Install the small, half-height jam nut first—against the hub. Tighten it up as hard as you comfortably can by hand with a standard wrench. Then, screw on the full-size nut and tighten that down independently—again, as hard as you comfortably can, by hand with a standard-size wrench.”

That’s it. If the wrench you use is the standard size for the nut you are tightening, this works fine.

Keep in mind that the propeller nuts aren’t really taking much load, and some load only in reverse. The propeller nuts purpose is to make sure the prop is seated snugly against the taper, and that the propeller can’t fall off. (Hate it when that happens.)

You could always refer to standard tables of bolt torque. You’d select the recommended torque for the bolt diameter of the nut and the material used in the propeller shaft. In don’t know of anyone who does this for prop nuts, however. -Dave Gerr, 3/6/2017

If you enjoyed this article, please subscribe so you won't miss anything as I keep building followingseas.media.